DC servo motor refers to the engine that controls the operation of mechanical components in the servo system. It is a device that assists the indirect speed change of the motor. Its main function: used in a closed loop, transmitting signals to the system at any time, and at the same time using the signals given by the system to correct its own operation. The low-voltage DC servo motor includes a stator, a rotor core, a motor shaft, a motor winding commutator, a motor winding, a speed measuring motor winding, and a speed measuring motor commutator. The rotor core is fixed on the motor shaft by laminating silicon steel stamping sheets. above composition. Low voltage DC servo motor has good speed control characteristics, can achieve smooth control in the entire speed range, almost no oscillation, small size, high efficiency, energy saving, low noise, no heat, and long life.

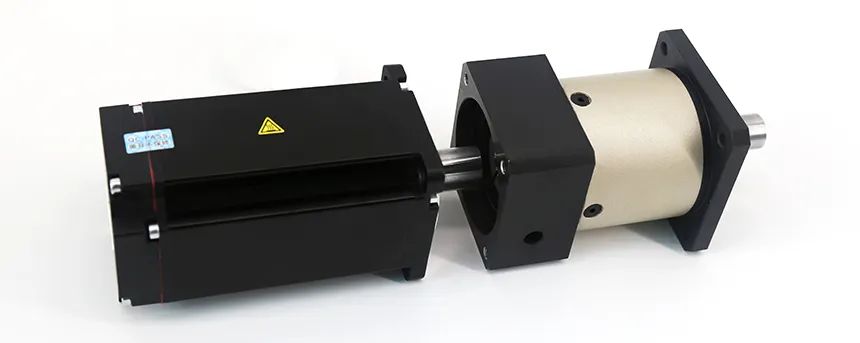

The servo motor reducer uses various levels of gear transmission to achieve the purpose of speed reduction. It is composed of various levels of gears. It is generally used for transmission equipment with low speed and high torque. It passes the power of electric motors, internal combustion engines or other high-speed operation through the reducer. The gear on the input shaft meshes with the large gear on the output shaft to achieve deceleration. The reducer is a power transmission mechanism that uses a gear speed converter to reduce the number of revolutions of the motor to the required number of revolutions and obtain a larger torque.

How to match the reducer according to the servo motor in practical applications?

1: Flange specifications

The cross-sectional size of the reducer is generally similar to the cross-sectional size of the motor. For other parameters, it is best to refer to the instructions of the selected brand. Technical samples generally indicate the selection steps and calculation examples. Specific models have different representations for each brand. Usually expressed roughly by the output flange size or cross-sectional size, generally there are 40 flange, 60 flange, 80 flange, 120 flange, 160 flange, 18 flange and other specifications.

2: speed ratio

The reduction ratio of the reducer is roughly selected as the motor rated speed divided by the final output speed. For example, if the final output speed is 200RPM and the rated speed of the motor is 3000RPM, then the speed ratio of the reducer is preferably about 1:15. The final output speed depends on the working conditions.

3: Torque

The rated torque of the reducer must be greater than or equal to the rated torque of the motor multiplied by the reduction ratio. Assuming that the rated torque of the motor is 10N.M and the reduction ratio is 15, then the rated torque of the selected reducer model must be greater than 10*15=150N.M.

4: Accuracy

The return clearance (backlash, clearance or rotational clearance) of the reducer depends on the specific work requirements. Generally speaking, the clearance used with the servo motor should not be greater than 20arcmin. Single-stage deceleration that can achieve less than or equal to 3arcmin is generally a high-end product.

General principles:

Small servo motors can be equipped with large reducers, but large motors are generally not equipped with small reducers.

The higher the rigidity of the same specifications, the better the quality, so our process is a hard tooth surface cutting process.

Servo motor selection:

Speed (select as needed)

Torque (calculate the torque that the servo motor needs to output based on the load structure, weight and speed)

Moment of inertia (this parameter is related to the running accuracy of the servo on the mechanical structure, calculated by the weight of the load structure)

Generally, a certain margin must be left, that is, a safety factor.

Use these three parameters combined with the selection sample to select the servo motor model.

Reducer selection:

Reduction ratio (finally determined based on the ratio of the motor's speed to the final required output speed, the ratio of the final required output torque to the motor torque, and the square root of the ratio of the mechanical moment of inertia to the motor's moment of inertia)

Rated load torque (the final output torque should not be greater than the rated torque of the reducer, which is related to the life of the reducer)

Accuracy (choose appropriate accuracy requirements according to user needs)

Installation matching dimensions (the matching installation between the load and the reducer and the matching installation between the motor and the reducer are determined according to the product drawings)

Since its establishment in 2013, Shenzhen Zhongling Technology Co., Ltd. has been focusing on the research and development, production and sales of industrial automation products. It is a national high-tech enterprise with multiple product patents. The products mainly include low-voltage DC servo motor driver series, robot hub motor driver series, brushless DC motor driver series, integrated stepper series, digital stepper motor driver series and digital closed-loop motor driver series and many other categories and models. Provide partners with cost-effective products and quality services.

Mailbox:[email protected]

Office address:303, 3rd Floor, Building B, Fenghuang Zhigu, Tiezi Road, Xixiang Street, Bao'an District, Shenzhen

Factory address:6th Floor, Building D, Changxing Zhigu Industrial Park, No. 16 Changlong Xinfeng Street, Huangjiang Town, Dongguan City