In modern society, people's productive labor is inseparable from various motors. It involves many fields, including aviation, coal mining, hydropower, etc. The role of the motor cannot be replaced. At the same time, the use, care and maintenance of motors are becoming more and more important.

In today's era, with the rapid development of the mobile robot industry, the application of hub servo motors is becoming more and more extensive, and it is increasingly necessary to improve its protection level.

The rotor and stator of hub servo motors are mostly made of magnetic iron (silicon steel), which is easily corroded in humid environments. At the same time, in order to optimize torque, the gap between the motor's rotating teeth and non-rotating teeth is kept at about 0.05mm.

As the motor runs, these rotor cogs heat up, often hot enough to turn any water in the motor into steam. Steam is corrosive, so the magnetic iron in the rotor teeth rusts faster than usual. Once rust fills the 0.05mm air gap, the rotor and stator teeth begin to rub, which removes the effective torque from the motor and loosens the magnetic iron.

If the rust is dry it will form a matte powder, if it is wet it will form a matte slurry. Once the oxide sludge enters the motor bearings, it acts as an abrasive and accelerates bearing wear. As the bearings wear, the centering of the rotor becomes less accurate, causing the rotor to wobble as it turns, eventually hitting the stator. Oxide buildup on the magnetic iron teeth and loss of bearing accuracy can cause motor failure in as little as two weeks. While the magnetic iron could be replaced with a non-corrosive metal, the metal would be more expensive and more expensive to process, and motor performance would be significantly reduced.

The main sealing structure of the hub servo motor is composed of four parts, namely the sealing of the front and rear end covers, the sealing of the bearing and the sealing of the cable outlet at the shaft end.

Front and rear end cover seals: Mainly through sealing rings to maintain sealing. The position of the sealing ring needs to avoid the screw holes on the end cover and steel ring, and the positioning point must be retained on the end cover. At the same time, it is necessary to avoid the sealing ring from taking up too much space, thereby affecting the precision of the motor.

Bearing seal: From the perspective of contact form, seals are mainly divided into two types: contact type and non-contact type.

Non-contact sealing, the simplest configuration is gap sealing. The oil groove seal evolved from the gap seal. It has several concentric oil grooves on the inner diameter of the bearing seat. The sealing effect is better. The lubricant stored in the oil groove can effectively prevent the entry of pollutants, dust, etc. In current engineering applications, labyrinth seals with oil sling rings are more commonly used, or in order to achieve better sealing effects, multi-layer labyrinth seals are used.

Contact seals include line contact and surface contact. The most common ones are Z-type seals, which are contact seal rings with a Z-shaped cross section. The Z is filled with grease inside to form a grease seal. Z-type seals are line contact seals. Z The "foot" part is in contact with the shaft. Among them, oil seal is the most commonly used contact seal.

Combination seals, as the name suggests, combine contact and non-contact seals. In some special application scenarios, in order to achieve the best sealing effect, you can consider the combination of contact seals and non-contact seals, such as Z-shaped sealing rings + labyrinth bearings to enhance the sealing effect of the Z-shaped sealing rings.

The sealing of the cable outlet at the shaft end can be achieved by adding a special structure at the end of the shaft. By continuously turning the nut, the nut continuously squeezes the sealing structure between the cable and the nut, thereby achieving good sealing. This structure is not only simple, but also can protect the cable from damage and maintain good sealing.

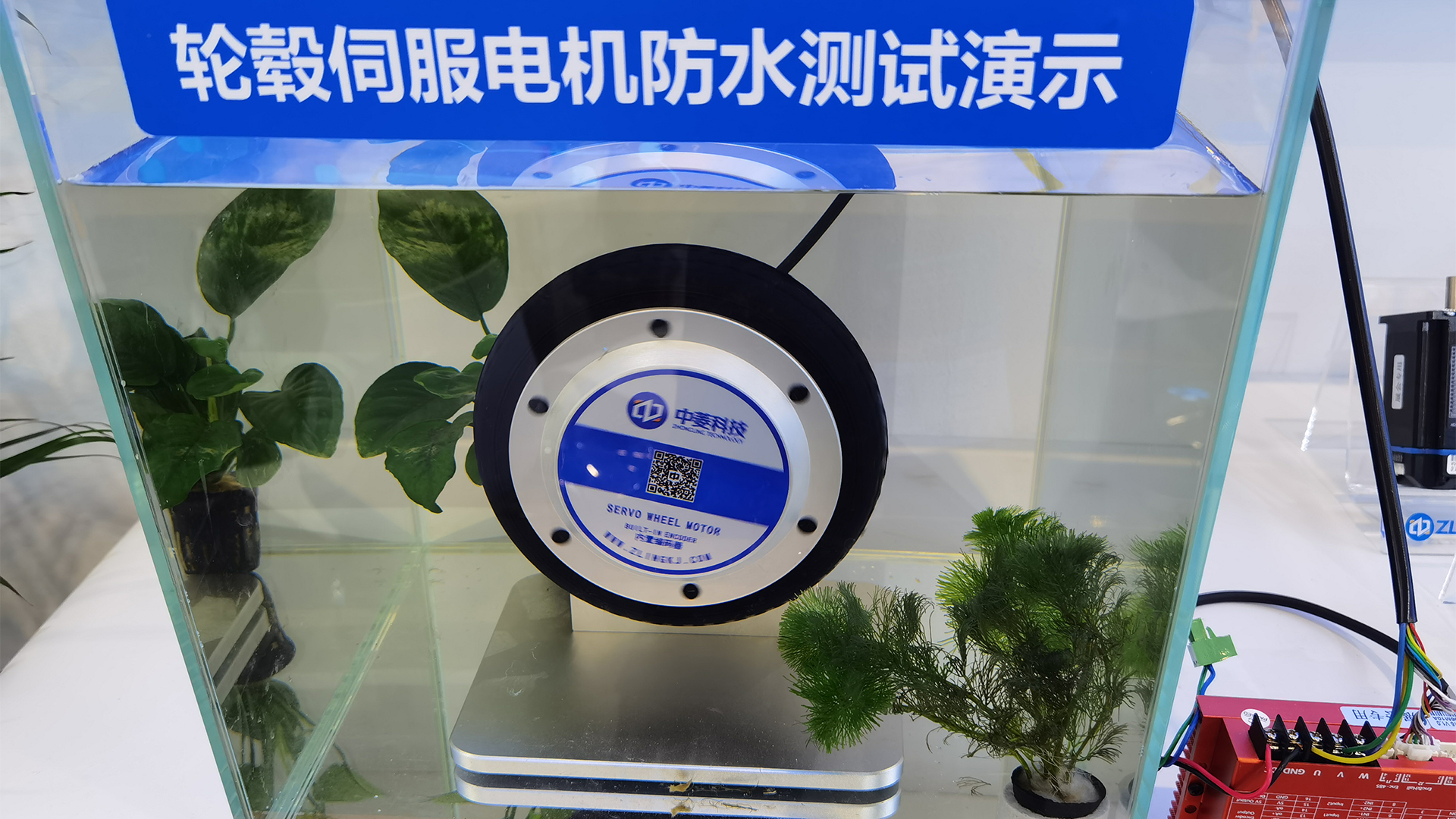

A group of outstanding teams who have been working on robot hub motors for many years - Shenzhen Zhongling Technology Team, has exquisitely designed the four important sealing parts of the hub motor, flexibly combined and used a variety of sealing structures, and developed a new waterproof hub servo motor. Moreover, this waterproof hub servo motor still performs well after two months of underwater testing and can still efficiently output torque and speed. Once this waterproof hub servo motor was launched, it shocked the entire mobile robot industry and aroused huge interest from countless mobile robot companies.

Mailbox:[email protected]

Office address:303, 3rd Floor, Building B, Fenghuang Zhigu, Tiezi Road, Xixiang Street, Bao'an District, Shenzhen

Factory address:6th Floor, Building D, Changxing Zhigu Industrial Park, No. 16 Changlong Xinfeng Street, Huangjiang Town, Dongguan City